Boiler Blast Machines

Boiler (Water Heater) Blast Machines & Tanks

Boiler blast machines are used for preparing the insides of water heaters for subsequent enamelling (wet or powder enamelling).

Boiler before blasting

Boiler after blasting

Depending on the handling system we offer semi-automatic and fully-automatic systems:

Semi-automatic blasting systems

Boiler blast facility with 1×3 stations

Without a transportation system water heaters are loaded/unloaded manually. According to the desired throughput 1, 2 or 3 boilers are processed at the same time. The shown machine features 3 combined blasting and cleaning stations:

Semi-automatic bloiler blast machine with 1×3 stations

Fully-automatic blasting equipment

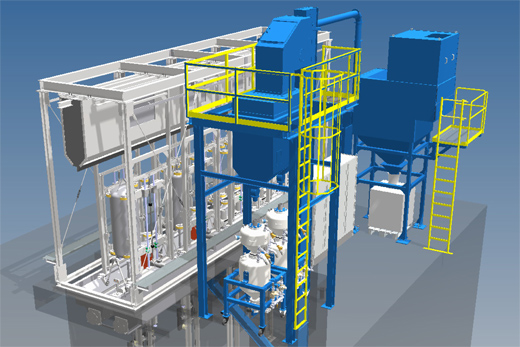

Boiler blast facility with 2×4 stations

In most cases this equipment is used in combination with a P+F conveyor system, occasionally also with a circular conveyor. According to specifications either 1, 2 or 4 boilers are processed simultaneously. The shown machine features 4 ea. blasting and cleaning (= air purging & rapping) stations and is loaded by a Power+Free conveyor:

Fully-automatic blast machine with 2×4 stations

Blast cabinet with blast generator, blast media reclaimer and dust collector

Processing of boilers

With fully-automatic boiler blast facilities each water heater first passes a blastcleaning station and then proceeds to an airpurging/rapping station (with semi-automatic machines both processes take place in a combined station).

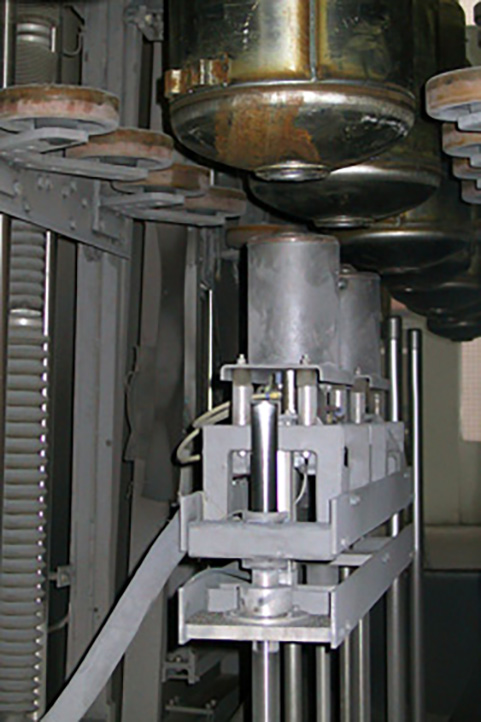

Positioning

Positioning of boilers is done pairwise by means of suspension frames:

Suspension frames ensure precise positioning of boilers

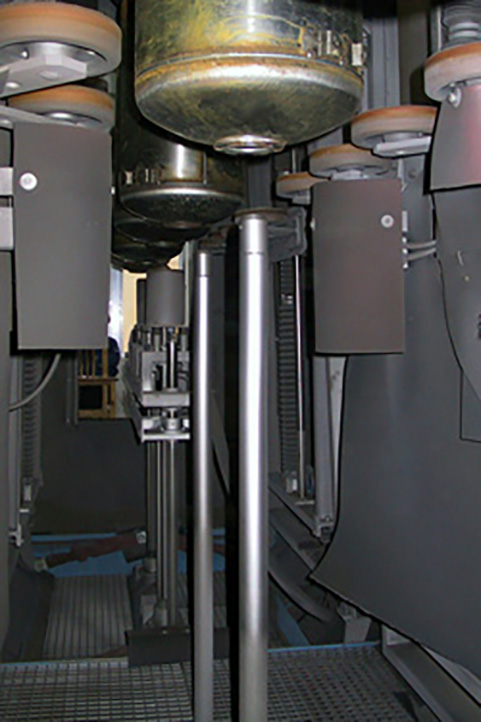

Blasting & cleaning

After positioning blast nozzles and air purging nozzles resp. move from below into the boilers. In the cleaning station boilers are additionally rapped pneumatically:

Blasting station

Cleaning station

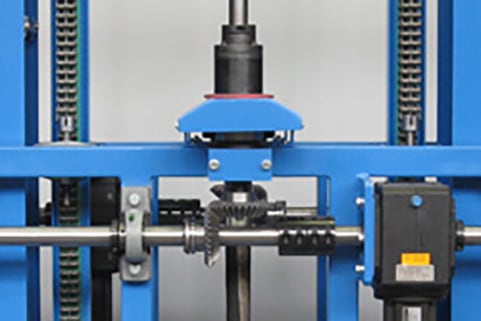

Boiler or lance rotation?

By default boilers are rotated during the blasting process. Optionally the lances can be rotated, e.g. if boiler rotation is not possible due to lateral extensions of the water heaters. Lance rotation alsois needed with so-called twin boilers.

Boiler rotation

Lance Rotation