Blast Cabinets

Economical and robust

Hand-Operated Blast Cabinets

Strahlkabinen werden von außen bedient. Während des Strahlvorganges wird verbrauchtes Strahlmittel über eine leistungsfähige Rückgewinnung kontinuierlich in den Kreislauf zurückgeführt und wieder aufbereitet. Staub, feine Partikel und Grobteile werden vom wiederverwendbaren Strahlmittel sorgfältig getrennt.

Pressure-fed blast cabinets

In the pressure-fed version blast media stored in the pressure vessel is metered into the air stream and directed with up to supersonic velocity at the workpiece through a specially designed nozzle. Pressure-fed blast machines are mainly used for:

- Rust removal

- Descaling

- Cleaning

- Paint stripping

- Roughening

- Shot Peening

For pressure-fed blasting mainly metallic media and aluminium oxide are used.

Suction-fed blast cabinets

In the suction-fed version the blast media is drawn to the nozzle by a venturi generated within a special gun assembly. Suction-fed blast machines are mainly used for

- Mattening

- Roughening

- Cleaning

For suction-fed blasting mainly non-metallic media such as glass beads and aluminium oxide are used.

Which kind of blast media?

With blast cabinets all kinds of recyclable blast media can be used such as aluminium oxide, glass beads, ceramic beads, steel grit, plastic media etc. One-way abrasives such as slags are not suitable.

Tailor-made options

Blast cabinets are available with a variety of optional equipment such as turntables, tumble baskets, multi-axis nozzle manipulators, runways with trolleys etc.:

Flexible solutions at your choice

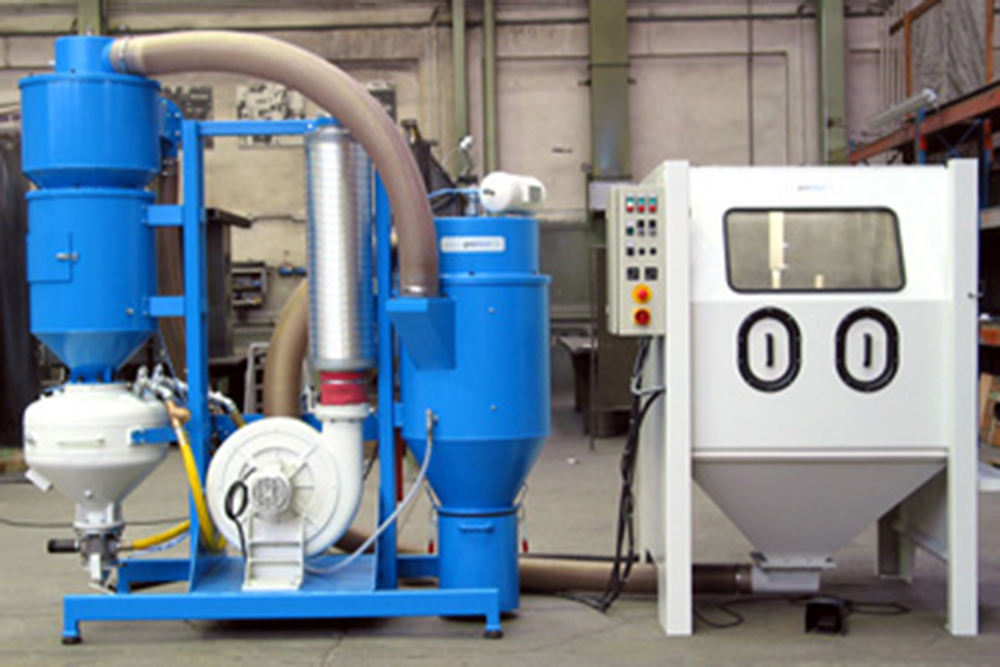

Particularly flexible solutions can be realized in combination with Problast® Powerpacks. Moreover, blast cabinets form the basis for many of our custom-made Machines.

Blast Cabinet with Problast Powerpack