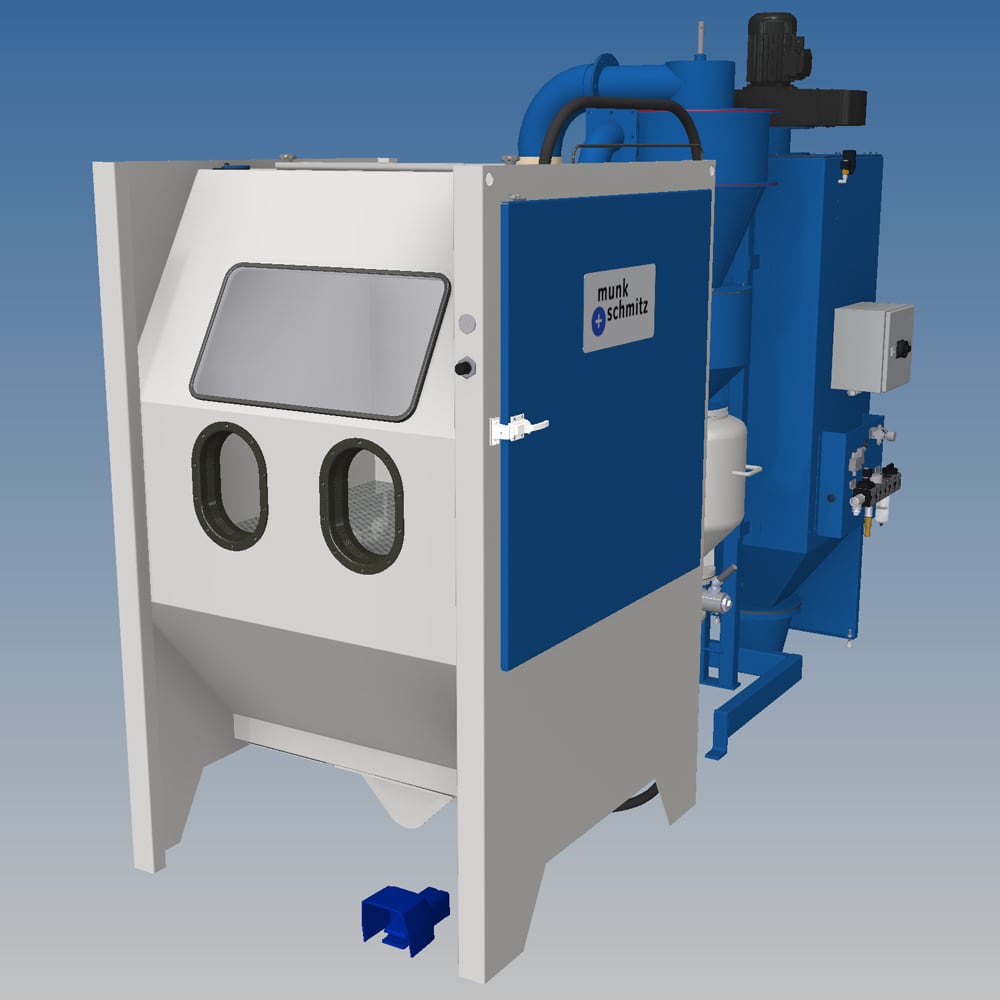

Pressure-fed blast cabinet MS 120 D

Blast cabinets are operated from the exterior. During blasting, spent blast media is recovered by an efficient reclaiming system and recycled. Dust, fine particles and debris are carefully separated from reusable blast media.

Machine type

Manually operated pressure-fed air blasting cabinet

Application

Rust removal, descaling, paint stripping, weld and

mould cleaning, roughening and etching

Assemblies

- Cabinet shell with gauntlet apertures, viewing window and side door, for handling/treatment of workpieces

- Pressure vessel with blast nozzle and blast hose, operation by foot switch

- Reclaimer with air cyclone and storage hopper, for separation of dust and reusable blast media

- Dust collector with fan and dust bin, for generation and dustcleaning of recovery air flow

- Maintenance unit for control of blasting pressure

Dimensions (WxDxH)

- Overall dimensions: 1230x1260x2000 mm

- Internal dimensions: 1200 x1155x930 mm

- Powerpack: 1100x1400x2510 mm

- Empty weight: 1100 kg

Blasting parameters

- Blast nozzle: 6.4 mm (boron carbide)

- Blasting cycle: max. 8 min

- Blast media storage capacity: max. 100 kg

- Air consumption: 1.7 m³/min

Dust collection

- Filter area: 21 m³

- Dust separation efficiency: > 99.9 %

- Energy consumption: 2.2 kW (16 A)

Welches Strahlmittel?

In Strahlkabinen können alle Strahlmittel zum Einsatz kommen, die eine Wiederaufbereitung zulassen, wie z.B. Korund, Glasperlen, Keramikperlen, Stahlguss usw. Einwegstrahlmittel wie z.B. Schlacke sind dagegen nicht geeignet.

Extensions à la Carte

Blast cabinets are available with a variety of optional equipment such as turntables, tumble baskets, multi-axis nozzle manipulators, runways with trolleys etc.: