Roller Blast Machines

Roller Blast Machines

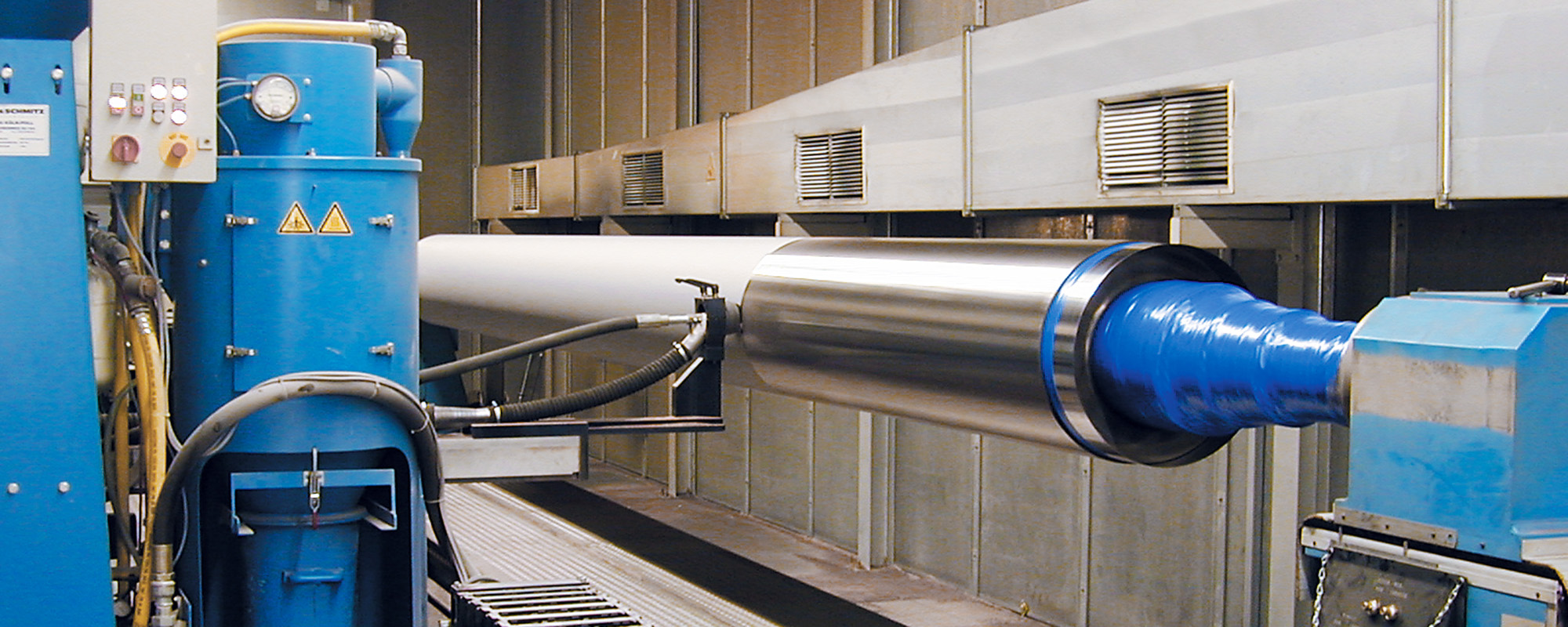

Problast® closed-circuit blast machines are ideally suited for the blasting of rollers. Cylinders can be blasted in normal production environment without enclosure by traversing the blast gun alongside the rotated roller. Etching, cleaning, roughening and creation of a non-stick surface are the most common applications.

Problast®

Closed-circuit machines for roller blasting

Problast® machines are typically operating in a closed-circuit mode, i. e. blast media is recycled by separating it from dust and debris. With special applications, if an a absolutely homogeneous roller surface must be achieved or if very fine blast media is used it is necessary to use the blast media only once. For these purposes special models are available which allow for both one-way and multi-way blasting.

Blast gun with flat brush

Video clip: Blasting of rollers

Video clip: Blasting of rollers

Blast gun with concave brush

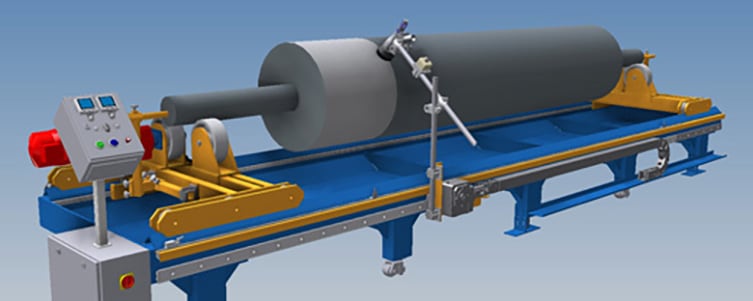

Stationary und mobile roller blast devices

Mobile roller blast devices allow for blastcleaning rollers in situ, such as in the plastic foil industry where calender rollers are etched in regular intervals to maintain consistent, uniform surface.

Stationary und mobile roller blast devices

Roller blast cabinets

Where due to the shape of the roller a blast gun cannot be used or where the roller has to be reworked manually we offer a variety of specially-engineered blast cabinets:

Sideloader with scissor lift table

Toploader with clamping spindle

Frontloader for needle rolls

Toploader for profile rolls

Combined Top-/Frontloader with automized traversing blast nozzles

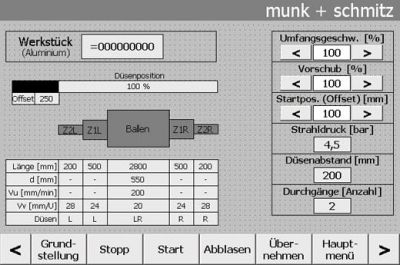

Control system à la carte

The control system forms the core of our automated roller blast machines. With the highest configuration level the following data may be stored and reproduced specifically for each type of roller: roll geometry, blasting speed, blast pressure, nozzle distance and no. of passages. In addition come control functions such as monitoring of blast media level an pressure difference of dust filter cartridges.

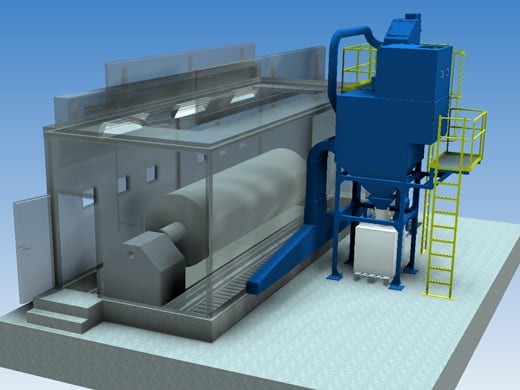

Blast rooms for roller blasting

If other workpieces must be blasted besides rollers, a walk-in blast room may be considered:

Roller blast room with rotating device